Factors txwv kev khiav hauj lwm temps

Cov ntawv thov uas xav tau cov ntaub ntawv duplex kom raug rau qhov kub thiab txias yog cov hlab ntsha siab, kiv cua / impellers lossis cov pa nqus pa.Cov kev xav tau ntawm cov khoom siv muaj peev xwm muaj peev xwm los ntawm kev siv tshuab siab mus rau corrosion kuj.Cov tshuaj lom neeg muaj pes tsawg leeg ntawm cov qib sib tham hauv kab lus no tau teev tseg hauv Table 1.

Spinodal decomposition

Spinodal decomposition (tseem hu ua demixing los yog keeb kwm li 475 ° C-embrittlement) yog hom kev sib cais ntawm theem ferritic, uas tshwm sim ntawm qhov kub txog 475 ° C.Cov txiaj ntsig tshaj plaws yog kev hloov pauv hauv microstructure, ua rau tsim ntawm α' theem, uas ua rau embrittlement ntawm cov khoom.Qhov no, nyob rau hauv lem, txwv qhov kev ua tau zoo ntawm cov khoom kawg.

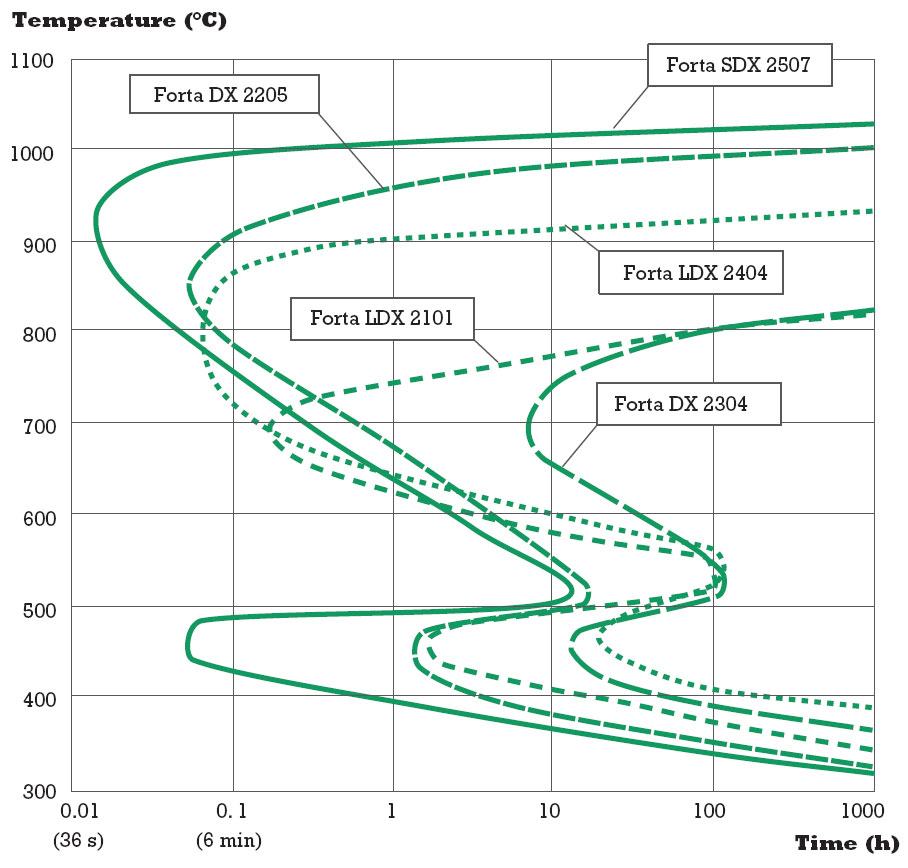

Daim duab 1 qhia txog qhov kub thiab txias lub sij hawm hloov pauv (TTT) daim duab rau cov ntaub ntawv duplex kawm, nrog spinodal decomposition sawv cev rau thaj tsam ntawm 475 ° C.Nws yuav tsum raug sau tseg tias daim duab TTT no sawv cev rau qhov txo qis ntawm qhov tawv nqaij los ntawm 50% ntsuas los ntawm kev cuam tshuam qhov kev sim ntawm cov qauv Charpy-V, uas feem ntau tau txais los ua qhov qhia txog kev sib tw.Hauv qee daim ntawv thov kev txo qis ntawm qhov hnyav tuaj yeem ua tau, uas hloov cov duab ntawm TTT daim duab.Yog li ntawd, qhov kev txiav txim siab los teeb tsa qhov siab tshaj plaws OT nyob ntawm seb qhov twg yog qhov kev lees paub ntawm embrittlement xws li toughness txo rau cov khoom kawg.Nws yuav tsum tau hais tias keeb kwm TTT-graphs kuj tau tsim los ntawm kev teeb tsa, xws li 27J.

Qib siab alloyed

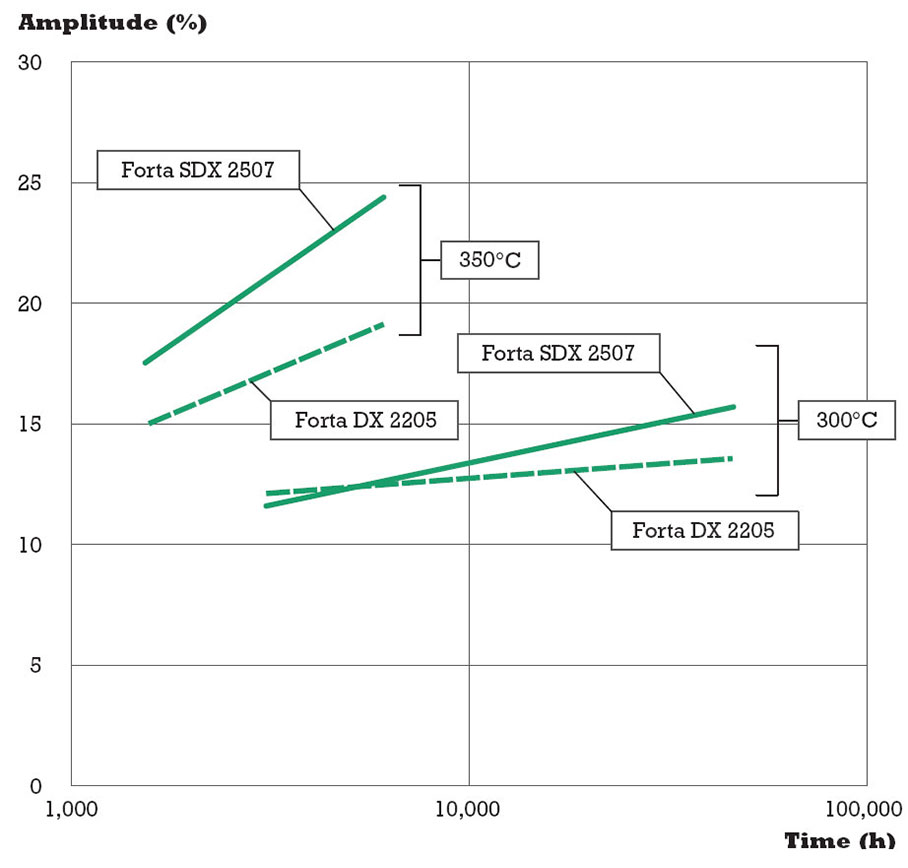

Daim duab 1 qhia tau hais tias qhov nce ntawm alloying ntsiab lus los ntawm qib LDX 2101 mus rau qib SDX 2507 ua rau kom tus nqi decomposition sai, whereas lean duplex qhia tau hais tias qeeb pib decomposition.Qhov cuam tshuam ntawm cov ntsiab lus alloying xws li chromium (Cr) thiab npib tsib xee (Ni) ntawm spinodal decomposition thiab embrittlement tau pom los ntawm kev tshawb nrhiav yav dhau los.5–8 Cov nyhuv no tau piav qhia ntxiv hauv daim duab 2. Nws qhia tau hais tias spinodal decomposition yog nce thaum kub. yog nce los ntawm 300 mus rau 350 ° C thiab sai dua rau cov qib siab alloyed SDX 2507 dua li rau tsawg alloyed DX 2205.

Qhov kev nkag siab no tuaj yeem yog qhov tseem ceeb hauv kev pab cov neeg siv khoom txiav txim siab txog qhov siab tshaj OT uas tsim nyog rau lawv cov qib thiab daim ntawv thov.

Kev ntsuas kub siab tshaj plaws

Raws li tau hais dhau los, qhov siab tshaj plaws OT rau cov khoom siv duplex tuaj yeem raug teeb tsa raws li qhov ua tau zoo ntawm qhov cuam tshuam toughness.Feem ntau, OT sib raug rau tus nqi ntawm 50% toughness txo tau txais yuav.

OT nyob ntawm temp & sijhawm

Txoj kab nqes hauv cov tails ntawm cov nkhaus hauv daim duab TTT hauv daim duab 1 qhia tau hais tias spinodal decomposition tsis tshwm sim tsuas yog nyob rau ntawm ib qho chaw pib kub thiab nres hauv qab theem ntawd.Hloov chaw, nws yog ib qho txheej txheem tas li thaum cov ntaub ntawv duplex raug rau kev khiav hauj lwm kub hauv qab 475 ° C.Txawm li cas los xij, nws tseem pom tseeb tias, vim qhov qis diffusion tus nqi qis dua, qhov ntsuas kub qis dua txhais tau tias decomposition yuav pib tom qab thiab ua qeeb qeeb.Yog li ntawd, siv cov khoom siv duplex ntawm qhov kub thiab txias yuav tsis ua teeb meem rau xyoo lossis ntau xyoo.Txawm li cas los xij tam sim no muaj kev nyiam los teeb tsa qhov siab tshaj plaws OT yam tsis xav txog lub sijhawm raug.Cov lus nug tseem ceeb yog vim li cas qhov kub-lub sij hawm ua ke yuav tsum tau siv los txiav txim seb nws puas muaj kev nyab xeeb siv cov khoom siv los yog tsis?Herzman et al.10 piav qhia txog qhov teeb meem no zoo: "...Qhov kev siv yuav raug txwv rau qhov kub thiab txias qhov twg cov kinetics ntawm demixing tsawg heev uas nws yuav tsis tshwm sim thaum lub sij hawm tsim technical life ntawm cov khoom ...".

Qhov cuam tshuam ntawm vuam

Cov ntawv thov feem ntau siv vuam los koom nrog cov khoom.Nws paub zoo tias cov weld microstructure thiab nws cov chemistry sib txawv ntawm cov khoom siv hauv paus 3.Nyob ntawm cov khoom siv muab tub lim, vuam txheej txheem thiab vuam tsis, qhov microstructure ntawm welds feem ntau txawv rau cov khoom siv ntau.Lub microstructure yog ib txwm coarser, thiab qhov no kuj suav nrog qhov kub-kub kub cuam tshuam cheeb tsam (HTHAZ), uas cuam tshuam rau spinodal decomposition hauv weldments.Qhov sib txawv ntawm microstructure ntawm bulk thiab weldments yog ib lub ntsiab lus tshuaj xyuas ntawm no.

Cov ntsiab lus txwv txwv

Cov tshooj dhau los ua rau cov lus xaus hauv qab no:

- Tag nrho cov ntaub ntawv duplex yog raug

mus rau spinodal decomposition ntawm kub ib ncig ntawm 475 ° C. - Nyob ntawm cov ntsiab lus alloying, yuav tsum muaj qhov nrawm dua lossis qeeb qeeb.Siab dua Cr thiab Ni cov ntsiab lus txhawb nqa kev sib xyaw kom nrawm dua.

- Txhawm rau teeb tsa qhov siab tshaj plaws ua haujlwm kub:

- Kev sib xyaw ua ke ntawm lub sijhawm ua haujlwm thiab qhov kub thiab txias yuav tsum tau txiav txim siab.

- Ib qho kev lees paub ntawm kev txo qis hauv toughness, piv txwv li, qhov xav tau ntawm qhov kawg toughness yuav tsum tau teeb tsa - Thaum cov khoom siv microstructural ntxiv, xws li welds, tau qhia, qhov siab tshaj OT yog txiav txim siab los ntawm qhov tsis muaj zog tshaj plaws.

Cov qauv thoob ntiaj teb

Ob peb European thiab Asmeskas cov qauv raug tshuaj xyuas rau qhov project no.Lawv tsom rau kev siv hauv cov hlab ntsha siab thiab cov kav dej.Feem ntau, qhov sib txawv ntawm qhov pom zoo tshaj plaws OT ntawm cov qauv tshuaj xyuas tuaj yeem muab faib ua European thiab Asmeskas qhov kev xav.

Cov txheej txheem European cov khoom siv tshwj xeeb rau cov hlau tsis muaj steel (xws li EN 10028-7, EN 10217-7) qhia txog qhov siab tshaj OT ntawm 250 ° C los ntawm qhov tseeb tias cov khoom siv tsuas yog muab txog qhov kub thiab txias.Ntxiv mus, European tsim qauv rau cov hlab ntsha siab thiab cov kav dej (EN 13445 thiab EN 13480, feem) tsis muab cov ntaub ntawv ntxiv txog qhov siab tshaj plaws OT los ntawm qhov tau muab rau hauv lawv cov qauv khoom siv.

Hauv qhov sib piv, Asmeskas cov khoom siv tshwj xeeb (xws li ASME SA-240 ntawm ASME ntu II-A) tsis nthuav tawm cov ntaub ntawv kub siab txhua.Cov ntaub ntawv no tau muab tso rau hauv ASME ntu II-D, 'Properties', uas txhawb nqa cov txheej txheem kev tsim kho dav dav rau cov hlab ntsha siab, ASME ntu VIII-1 thiab VIII-2 (tom kawg muab txoj hauv kev tsim ntau dua).Nyob rau hauv ASME II-D, qhov siab tshaj plaws OT yog qhia meej raws li 316 ° C rau feem ntau duplex alloys.

Rau kev siv cov kav dej siab, ob qho tib si tsim cov cai thiab cov khoom siv tau muab rau hauv ASME B31.3.Nyob rau hauv cov cai no, txhua yam ntaub ntawv yog muab rau duplex alloys mus txog 316 ° C yam tsis muaj ib daim ntawv qhia meej ntawm qhov siab tshaj OT.Txawm li cas los xij, koj tuaj yeem txhais cov ntaub ntawv kom ua raws li cov lus sau hauv ASME II-D, thiab yog li, qhov siab tshaj plaws OT rau Asmeskas cov qauv yog feem ntau 316 ° C.

Ntxiv nrog rau qhov siab tshaj plaws OT cov ntaub ntawv, ob qho tib si Asmeskas thiab European cov qauv qhia tau hais tias muaj kev pheej hmoo ntawm kev ntsib embrittlement ntawm qhov kub siab (> 250 ° C) ntawm lub sijhawm ntev dua, uas tom qab ntawd yuav tsum tau txiav txim siab nyob rau hauv ob qho tib si tsim thiab kev pabcuam theem.

Rau welds, feem ntau cov qauv tsis ua cov lus ruaj khov ntawm qhov cuam tshuam ntawm spinodal decomposition.Txawm li cas los xij, qee cov qauv (xws li ASME VIII-1, Table UHA 32-4) qhia tau tias muaj peev xwm ua cov kev kho cua sov tom qab vuam.Cov no tsis tas yuav tsum tau lossis txwv tsis pub, tab sis thaum ua lawv yuav tsum tau ua raws li cov txheej txheem ua ntej hauv cov qauv.

Qhov kev lag luam hais li cas

Cov ntaub ntawv tsim los ntawm ob peb lwm cov tuam txhab ntawm duplex stainless hlau tau tshuaj xyuas kom pom tias lawv sib txuas lus dab tsi txog qhov kub thiab txias rau lawv cov qib.2205 yog txwv ntawm 315 ° C los ntawm ATI, tab sis Acerinox teeb tsa OT rau tib qib ntawm tsuas yog 250 ° C.Cov no yog cov txwv OT sab sauv thiab qis rau qib 2205, thaum nyob nruab nrab ntawm lawv lwm cov OTs tau sib tham los ntawm Aperam (300 ° C), Sandvik (280 ° C) thiab ArcelorMittal (280 ° C).Qhov no qhia tau hais tias qhov dav ntawm qhov pom zoo tshaj plaws OTs tsuas yog rau ib qib uas yuav muaj cov khoom zoo sib xws los ntawm cov chaw tsim khoom mus rau cov chaw tsim khoom.

Cov keeb kwm yav dhau los hais txog vim li cas cov chaw tsim khoom tau teeb tsa qee yam OT tsis yog ib txwm qhia.Feem ntau, qhov no yog raws li ib qho qauv tshwj xeeb.Cov qauv sib txawv sib txuas lus sib txawv OTs, yog li kev sib kis ntawm cov txiaj ntsig.Qhov kev txiav txim siab yog tias cov tuam txhab Asmeskas tau teeb tsa tus nqi siab dua vim cov lus hais hauv ASME tus qauv, thaum cov tuam txhab European teeb tsa tus nqi qis dua vim yog EN tus qauv.

Cov neeg siv khoom xav tau dab tsi?

Nyob ntawm daim ntawv thov zaum kawg, ntau yam kev thauj khoom thiab nthuav tawm ntawm cov ntaub ntawv yuav tsum tau ua.Hauv qhov project no, embrittlement vim spinodal decomposition yog feem ntau txaus siab vim nws muaj feem xyuam rau cov hlab ntsha siab.

Txawm li cas los xij, muaj ntau yam kev siv uas nthuav tawm cov qib duplex rau nruab nrab cov khoom siv thauj khoom nkaus xwb, xws li scrubbers11-15.Lwm qhov kev thov yog cuam tshuam nrog cov kiv cua thiab cov impellers, uas raug rau kev qaug zog loads.Cov ntaub ntawv qhia tau hais tias spinodal decomposition coj txawv thaum muaj kev qaug zog load15.Nyob rau theem no, nws paub tseeb tias qhov siab tshaj OT ntawm cov ntawv thov no tsis tuaj yeem teeb tsa tib yam li rau cov hlab ntsha siab.

Lwm chav kawm ntawm kev thov tsuas yog rau kev siv tshuaj tiv thaiv corrosion nkaus xwb, xws li marine exhaust gas scrubbers.Nyob rau hauv cov ntaub ntawv no, corrosion kuj yog ib qho tseem ceeb tshaj li OT txwv nyob rau hauv ib tug neeg kho tshuab load.Txawm li cas los xij, ob qho tib si cuam tshuam rau kev ua haujlwm ntawm cov khoom kawg, uas yuav tsum tau txiav txim siab thaum qhia qhov siab tshaj OT.Ntxiv dua thiab, rooj plaub no txawv ntawm ob rooj plaub dhau los.

Zuag qhia tag nrho, thaum qhia tus neeg siv khoom ntawm qhov tsim nyog siab tshaj OT rau lawv qib duplex, hom kev thov yog qhov tseem ceeb hauv kev teeb tsa tus nqi.Qhov no qhia ntxiv txog qhov nyuaj ntawm kev teeb tsa ib qho OT rau ib qib, vim tias ib puag ncig uas cov khoom siv tau ua rau muaj kev cuam tshuam loj rau cov txheej txheem embrittlement.

Qhov siab tshaj plaws ua haujlwm kub rau duplex yog dab tsi?

Raws li tau hais, qhov siab tshaj plaws kev khiav hauj lwm kub yog teem los ntawm tsawg heev kinetics ntawm spinodal decomposition.Tab sis peb ntsuas qhov ntsuas kub no li cas thiab qhov "tsawg kinetics" yog dab tsi?Cov lus teb rau thawj lo lus nug yog ib qho yooj yim.Peb twb tau hais tias kev ntsuas toughness yog feem ntau ua los kwv yees tus nqi thiab kev nce qib ntawm decomposition.Qhov no yog teev nyob rau hauv cov qauv ua raws li los ntawm feem ntau manufacturers.

Qhov thib ob lo lus nug, ntawm dab tsi yog txhais los ntawm qis kinetics thiab tus nqi uas peb teem ib tug kub ciam teb yog complex.Qhov no yog ib nrab txij li cov ciam teb ntawm qhov kub siab tshaj plaws tau muab tso ua ke los ntawm ob qho tib si qhov kub siab tshaj plaws (T) nws tus kheej thiab lub sijhawm ua haujlwm (t) tshaj qhov ntsuas kub ntawm qhov no.Txhawm rau kom ntseeg tau qhov kev sib xyaw ua ke ntawm Tt no, ntau yam kev txhais ntawm "qis tshaj" toughness tuaj yeem siv:

• Cov ciam teb qis, uas tau teev tseg hauv keeb kwm thiab tuaj yeem thov rau welds yog 27 Joules (J)

• Nyob rau hauv cov qauv feem ntau 40J yog teem raws li kev txwv.

• 50% txo qis hauv qhov pib toughness kuj nquag siv los teeb tsa tus ciam teb qis dua.

Qhov no txhais tau hais tias ib nqe lus ntawm qhov siab tshaj plaws OT yuav tsum yog raws li tsawg kawg peb qhov kev pom zoo:

• Kub-lub sij hawm raug ntawm cov khoom kawg

• Qhov tsawg kawg nkaus tus nqi ntawm toughness

• Qhov kawg ntawm daim ntawv thov (chemistry nkaus xwb, mechanical load yog/tsis yog thiab lwm yam.)

Ua ke kev sim kev paub

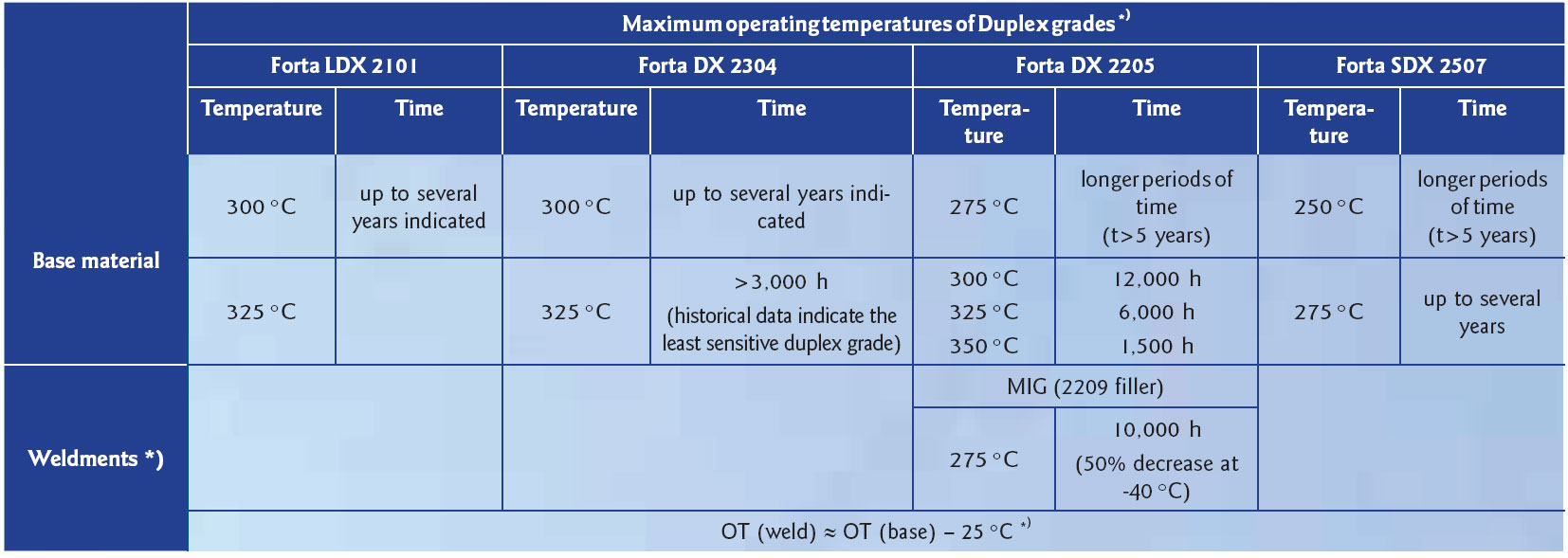

Ua raws li kev soj ntsuam dav dav ntawm cov ntaub ntawv kev sim thiab cov qauv, nws tau tuaj yeem sau cov lus pom zoo rau plaub qib duplex nyob rau hauv kev tshuaj xyuas, saib Table 3. Nws yuav tsum raug lees paub tias feem ntau ntawm cov ntaub ntawv yog tsim los ntawm cov kev sim hauv chav sim ua nrog ntsuas kub ntawm 25 ° C. .

Nws tseem yuav tsum tau muab sau tseg tias cov lus pom zoo no ua rau siv tsawg kawg yog 50% ntawm qhov toughness seem ntawm RT.Thaum nyob rau hauv lub rooj "ntev lub sij hawm ntev" qhia tias tsis muaj qhov txo qis ntawm RT tau raug sau tseg.Tsis tas li ntawd, qhov vuam tsuas yog raug kuaj ntawm -40 ° C.Thaum kawg, nws yuav tsum tau muab sau tseg tias lub sij hawm ntev raug cia siab rau DX 2304, xav txog nws lub siab tawv tom qab 3,000 teev ntawm kev sim.Txawm li cas los xij, qhov twg qhov nthuav dav tuaj yeem nce ntxiv yuav tsum tau txheeb xyuas nrog kev sim ntxiv.

Nws muaj peb lub ntsiab lus tseem ceeb uas yuav tsum nco ntsoov:

• Cov kev tshawb pom tam sim no qhia tau hais tias yog cov welds tam sim no, OT yuav txo qis li ntawm 25 ° C.

• Lub sij hawm luv luv (tsawg teev ntawm T = 375 ° C) yog siv tau rau DX 2205. Raws li DX 2304 thiab LDX 2101 yog cov qib qis alloyed, piv rau lub sij hawm luv luv kub spikes yuav tsum tau txais thiab.

• Thaum cov khoom yog embrittled vim decomposition, mitigation tshav kub kev kho mob ntawm 550 - 600 ° C rau DX 2205 thiab 500 ° C rau SDX 2507 rau 1 teev pab kom rov qab lub toughness los ntawm 70%.

Post lub sij hawm: Feb-04-2023