Duplex Stainless Hlau - Superduplex

Hauv metallurgy, stainless hlau yog cov hlau alloy nrog tsawg kawg yog 10.5% chromium nrog lossis tsis muaj lwm yam alloying ntsiab lus thiab qhov siab tshaj ntawm 1.2% carbon los ntawm huab hwm coj.Stainless hlau, tseem hu ua inox steels los yog inox los ntawm Fabkis inoxydable (inoxidizable), yoghlau alloysuas paub zoo heev rau lawv cov kev tiv thaiv corrosion, uas nce ntxiv nrog cov ntsiab lus chromium.Corrosion kuj tseem tuaj yeem txhim kho los ntawm nickel thiab molybdenum ntxiv.Qhov tsis kam ntawm cov hlau alloys rau cov tshuaj lom neeg ntawm cov neeg ua haujlwm corrosive yog raws li passivation.Rau passivation tshwm sim thiab nyob ruaj khov, Fe-Cr alloy yuav tsum muaj qhov tsawg kawg nkaus chromium cov ntsiab lus ntawm li 10.5% los ntawm qhov hnyav, saum toj no uas passivity tuaj yeem tshwm sim thiab hauv qab no tsis tuaj yeem.Chromium tuaj yeem siv los ua cov khoom tawv tawv thiab feem ntau siv nrog cov khoom tawv tawv xws li npib tsib xee los tsim cov khoom zoo tshaj plaws.

Duplex Stainless Hlau

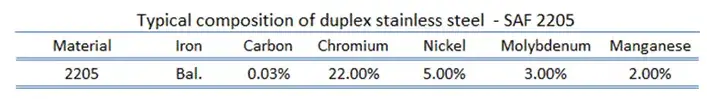

Raws li lawv lub npe qhia, Duplex stainless hlau yog kev sib xyaw ntawm ob hom hlau loj.Lawv muaj ib tug sib xyaw microstructure ntawm austenite thiab ferrite, lub hom phiaj feem ntau yog los tsim ib tug 50/50 mix, txawm hais tias, nyob rau hauv kev lag luam alloys, tus piv yuav yog 40/60.Lawv cov corrosion kuj zoo ib yam li lawv cov austenitic counterparts, tab sis lawv cov kev ntxhov siab-corrosion tsis kam (tshwj xeeb tshaj yog rau chloride kev nyuaj siab corrosion cracking), tensile zog, thiab yield zog (kwv yees li ob zaug lub zog tawm los ntawm austenitic stainless hlau) feem ntau superior rau cov austenitic. qib.Hauv duplex stainless hlau, carbon yog khaws cia rau qib qis heev (C <0.03%).Chromium cov ntsiab lus nyob ntawm 21.00 txog 26.00%, nickel cov ntsiab lus nyob ntawm 3.50 txog 8.00%, thiab cov alloys no yuav muaj molybdenum (txog 4.50%).Toughness thiab ductility feem ntau poob ntawm cov qib austenitic thiab ferritic.Cov qib Duplex feem ntau muab faib ua peb pawg raws li lawv cov kev tiv thaiv corrosion: lean duplex, standard duplex, thiab superduplex.Superduplex steels tau txhim kho lub zog thiab ua haujlwm rau txhua hom kev xeb piv rau cov qauv austenitic steels.Cov kev siv feem ntau suav nrog kev siv dej hiav txwv, cov nroj tsuag petrochemical, cov nroj tsuag desalination, cov khoom siv hluav taws xob, thiab kev lag luam papermaking.Niaj hnub no, kev lag luam roj thiab roj yog cov neeg siv loj tshaj plaws thiab tau thawb ntau qib corrosion-resistant, ua rau kev txhim kho ntawm superduplex steels.

Kev tiv thaiv ntawm stainless hlau rau cov tshuaj lom neeg cov tshuaj corrosive yog raws li passivation.Rau passivation tshwm sim thiab nyob ruaj khov, Fe-Cr alloy yuav tsum muaj qhov tsawg kawg nkaus chromium cov ntsiab lus ntawm li 10.5% los ntawm qhov hnyav, saum toj no uas passivity tuaj yeem tshwm sim thiab hauv qab no tsis tuaj yeem.Chromium tuaj yeem siv los ua cov khoom tawv tawv thiab feem ntau siv nrog cov khoom tawv tawv xws li npib tsib xee los tsim cov khoom zoo tshaj plaws.

Duplex Stainless Hlau - SAF 2205 - 1.4462

Ib hom duplex stainless hlau yog SAF 2205 (ib lub cim lag luam Sandvik rau 22Cr duplex (ferritic-austenitic) stainless hlau), uas feem ntau muaj 22% chromium thiab 5% npib tsib xee.Nws muaj kev tiv thaiv corrosion zoo heev thiab lub zog siab, 2205 yog cov khoom siv dav siv duplex stainless hlau.Daim ntawv thov ntawm SAF 2205 yog nyob rau hauv cov lag luam hauv qab no:

- Kev thauj mus los, kev cia khoom, thiab kev ua tshuaj lom neeg

- Cov cuab yeej ua haujlwm

- High chloride thiab marine ib puag ncig

- Kev tshawb nrhiav roj thiab roj

- Cov tshuab ntawv

Cov khoom ntawm Duplex Stainless Hlau

Cov khoom siv yog cov khoom siv hnyav, uas txhais tau hais tias lawv muaj kev ywj pheej ntawm qhov loj thiab tuaj yeem sib txawv ntawm qhov chaw mus rau qhov chaw hauv lub cev txhua lub sijhawm.Cov ntaub ntawv tshawb fawb suav nrog kev kawm cov ntaub ntawv cov qauv thiab hais txog lawv cov khoom (mechanical, hluav taws xob, thiab lwm yam).Thaum tus kws tshawb fawb cov ntaub ntawv paub txog qhov kev sib raug zoo ntawm cov khoom vaj khoom tsev no, lawv tuaj yeem mus kawm txog qhov txheeb ze ntawm cov khoom siv hauv daim ntawv thov.Cov kev txiav txim loj ntawm cov qauv ntawm cov khoom siv thiab yog li ntawm nws cov khoom yog nws cov khoom siv tshuaj lom neeg thiab yuav ua li cas nws tau ua tiav rau hauv nws daim ntawv kawg.

Mechanical Properties ntawm Duplex Stainless Hlau

Cov ntaub ntawv feem ntau raug xaiv rau ntau daim ntawv thov vim tias lawv muaj qhov xav tau kev sib txuas ntawm cov yam ntxwv ntawm cov tshuab.Rau kev siv cov qauv, cov khoom siv yog qhov tseem ceeb thiab cov engineers yuav tsum coj mus rau hauv tus account.

Lub zog ntawm Duplex Stainless Hlau

Nyob rau hauv lub mechanics ntawm cov ntaub ntawv, lublub zog ntawm cov khoomNws muaj peev xwm tiv taus ib qho kev thov tsis ua haujlwm lossis cov yas deformation.Lub zog ntawm cov ntaub ntawv txiav txim siab txog kev sib raug zoo ntawm cov khoom siv sab nraud uas siv rau cov khoom siv thiab qhov tshwm sim deformation lossis hloov pauv ntawm cov khoom loj.Lub zog ntawm cov khoom siv yog nws lub peev xwm los tiv thaiv qhov kev thov no yam tsis muaj kev ua haujlwm lossis cov yas deformation.

Qhov kawg Tensile Strength

Qhov kawg tensile lub zog ntawm duplex stainless hlau - SAF 2205 yog 620 MPa.

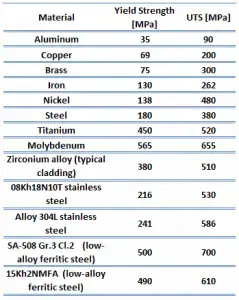

Covqhov kawg tensile zogyog qhov siab tshaj plaws ntawm engineeringstress-strain nkhaus.Qhov no sib raug rau qhov siab tshaj plaws kev ntxhov siab txhawb nqa los ntawm cov qauv hauv kev nro.Lub zog tensile kawg feem ntau luv luv rau "lub zog tensile" lossis "qhov kawg."Yog tias qhov kev ntxhov siab no tau siv thiab khaws cia, qhov tawg yuav tshwm sim.Feem ntau, tus nqi no tseem ceeb tshaj qhov kev ntxhov siab tawm los (ntau npaum li 50 mus rau 60 feem pua ntau tshaj qhov tawm los rau qee hom hlau).Thaum cov khoom siv hluav taws xob nce mus txog nws lub zog kawg, nws muaj kev paub txog caj dab qhov twg qhov chaw hla ntu txo qis hauv zos.Lub zog-strain nkhaus tsis muaj kev ntxhov siab ntau dua li qhov kawg ntawm lub zog.Txawm hais tias deformations tuaj yeem nce ntxiv, qhov kev ntxhov siab feem ntau txo qis tom qab ua tiav lub zog kawg.Nws yog ib qho cuab yeej siv zog;yog li ntawd, nws tus nqi tsis nyob ntawm qhov loj ntawm cov qauv kuaj.Txawm li cas los xij, nws nyob ntawm lwm yam, xws li kev npaj ntawm cov qauv, qhov muaj lossis lwm yam ntawm qhov chaw tsis xws luag, thiab qhov ntsuas kub ntawm qhov chaw kuaj thiab cov khoom siv.Qhov kawg tensile zog sib txawv ntawm 50 MPa rau txhuas kom siab li 3000 MPa rau cov hlau muaj zog heev.

Covqhov kawg tensile zogyog qhov siab tshaj plaws ntawm engineeringstress-strain nkhaus.Qhov no sib raug rau qhov siab tshaj plaws kev ntxhov siab txhawb nqa los ntawm cov qauv hauv kev nro.Lub zog tensile kawg feem ntau luv luv rau "lub zog tensile" lossis "qhov kawg."Yog tias qhov kev ntxhov siab no tau siv thiab khaws cia, qhov tawg yuav tshwm sim.Feem ntau, tus nqi no tseem ceeb tshaj qhov kev ntxhov siab tawm los (ntau npaum li 50 mus rau 60 feem pua ntau tshaj qhov tawm los rau qee hom hlau).Thaum cov khoom siv hluav taws xob nce mus txog nws lub zog kawg, nws muaj kev paub txog caj dab qhov twg qhov chaw hla ntu txo qis hauv zos.Lub zog-strain nkhaus tsis muaj kev ntxhov siab ntau dua li qhov kawg ntawm lub zog.Txawm hais tias deformations tuaj yeem nce ntxiv, qhov kev ntxhov siab feem ntau txo qis tom qab ua tiav lub zog kawg.Nws yog ib qho cuab yeej siv zog;yog li ntawd, nws tus nqi tsis nyob ntawm qhov loj ntawm cov qauv kuaj.Txawm li cas los xij, nws nyob ntawm lwm yam, xws li kev npaj ntawm cov qauv, qhov muaj lossis lwm yam ntawm qhov chaw tsis xws luag, thiab qhov ntsuas kub ntawm qhov chaw kuaj thiab cov khoom siv.Qhov kawg tensile zog sib txawv ntawm 50 MPa rau txhuas kom siab li 3000 MPa rau cov hlau muaj zog heev.

Yield zog

Lub zog ntawm duplex stainless hlau - SAF 2205 yog 440 MPa.

Covyield pointyog qhov point ntawm astress-strain nkhausuas qhia txog qhov txwv ntawm kev coj tus cwj pwm elastic thiab pib tus cwj pwm yas.Yield zog los yog yield stress yog cov cuab yeej cuab tam uas txhais raws li qhov kev nyuaj siab uas cov khoom pib deform plastically.Nyob rau hauv sib piv, qhov taw tes tawm los yog qhov chaw uas tsis yog linear (elastic + yas) deformation pib.Ua ntej qhov taw tes tawm, cov khoom siv yuav deform elastically thiab rov qab mus rau nws cov duab qub thaum lub zog thov raug tshem tawm.Thaum qhov taw tes tawm los dhau lawm, qee feem ntawm qhov deformation yuav ruaj khov thiab tsis thim rov qab.Qee cov hlau thiab lwm yam ntaub ntawv nthuav tawm tus cwj pwm hu ua qhov tshwm sim ntawm qhov tshwm sim.Cov khoom muaj zog sib txawv ntawm 35 MPa rau cov hlau tsis tshua muaj zog rau ntau dua 1400 MPa rau cov hlau muaj zog.

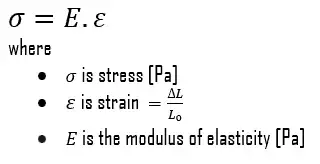

Young's Modulus ntawm Elasticity

Young's modulus ntawm elasticity ntawm duplex stainless hlau - SAF 2205 yog 200 GPa.

Young's modulus ntawm elasticityyog lub elastic modulus rau tensile thiab compressive kev nyuaj siab nyob rau hauv lub linear elasticity tswj ntawm ib tug uniaxial deformation thiab feem ntau yog ntsuas los ntawm tensile xeem.Txog rau kev txwv kev ntxhov siab, lub cev yuav tuaj yeem rov qab tau nws qhov ntev ntawm kev tshem tawm ntawm lub nra.Cov kev ntxhov siab ua rau cov atoms nyob rau hauv ib lub siv lead ua txav ntawm lawv txoj hauj lwm sib npaug, thiab tag nrho covatomsraug tshem tawm tib tus nqi thiab tuav lawv cov txheeb ze geometry.Thaum cov kev ntxhov siab raug tshem tawm, tag nrho cov atoms rov qab mus rau lawv qhov chaw qub, thiab tsis muaj deformation mus tas li.Raws liHook's law, qhov kev ntxhov siab yog proportional to strain (hauv thaj tsam elastic), thiab txoj kab nqes yog Young's modulus.Young's modulus yog sib npaug rau longitudinal kev nyuaj siab muab faib los ntawm lub hom.

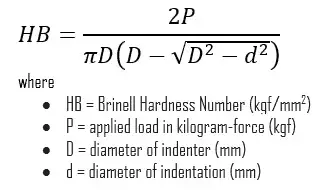

Lub hardness ntawm Duplex Stainless hlau

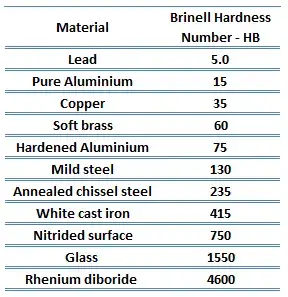

Brinell hardness ntawm duplex stainless hlau - SAF 2205 yog kwv yees li 217 MPa.

Hauv cov ntaub ntawv science,tawvyog lub peev xwm los tiv thaiv nto indentation (localized yas deformation) thiab khawb.Hardness yog tej zaum cov khoom siv tsis zoo tshaj plaws vim tias nws yuav qhia tau tias muaj kev tiv thaiv khawb, puas ntsoog, indentation, los yog kev tiv thaiv rau shaping lossis localized yas deformation.Hardness yog ib qho tseem ceeb los ntawm ib qho kev pom zoo engineering vim tias tsis kam hnav los ntawm kev sib txhuam los yog yaig los ntawm chav, roj, thiab dej feem ntau nce nrog hardness.

Hauv cov ntaub ntawv science,tawvyog lub peev xwm los tiv thaiv nto indentation (localized yas deformation) thiab khawb.Hardness yog tej zaum cov khoom siv tsis zoo tshaj plaws vim tias nws yuav qhia tau tias muaj kev tiv thaiv khawb, puas ntsoog, indentation, los yog kev tiv thaiv rau shaping lossis localized yas deformation.Hardness yog ib qho tseem ceeb los ntawm ib qho kev pom zoo engineering vim tias tsis kam hnav los ntawm kev sib txhuam los yog yaig los ntawm chav, roj, thiab dej feem ntau nce nrog hardness.

Brinell hardness xeemyog ib qho ntawm indentation hardness tests tsim rau hardness kuaj.Hauv kev ntsuam xyuas Brinell, ib qho nyuaj, kheej kheej indenter raug yuam kom nyob rau hauv ib qho kev thauj khoom tshwj xeeb rau hauv qhov chaw ntawm cov hlau los kuaj.Qhov kev ntsuam xyuas raug siv 10 hli (0.39 nyob rau hauv) txoj kab uas hla hardened steel pob ua ib qho indenter nrog 3,000 kgf (29.42 kN; 6,614 lbf) quab yuam.Lub load yog khaws cia tas mus li rau lub sijhawm teev tseg (nruab nrab ntawm 10 thiab 30 s).Rau cov ntaub ntawv softer, siv lub zog me me;rau cov ntaub ntawv nyuaj, lub pob tungsten carbide tau hloov pauv rau lub pob steel.

Qhov kev ntsuam xyuas muab cov lej ntsuas los ntsuas qhov hardness ntawm cov khoom, uas qhia los ntawm Brinell hardness tooj - HB.Tus naj npawb Brinell hardness yog tsim los ntawm cov qauv siv feem ntau siv (ASTM E10-14 [2] thiab ISO 6506-1: 2005) raws li HBW (H los ntawm hardness, B los ntawm Brinell, thiab W los ntawm cov khoom ntawm indenter, tungsten (wolfram) carbide).Hauv cov qauv qub, HB lossis HBS tau siv los xa mus rau kev ntsuas ua nrog steel indenters.

Lub Brinell hardness tooj (HB) yog cov load muab faib los ntawm qhov chaw ntawm lub indentation.Txoj kab uas hla ntawm qhov kev xav yog ntsuas nrog lub tshuab ntsuas nrog lub ntsuas superimposed.Brinell hardness tooj yog xam los ntawm qhov sib npaug:

Muaj ntau txoj hauv kev sim siv ntau yam (piv txwv li, Brinell,Knoop,Vickers, thiabRockwell).Muaj cov rooj uas muaj qhov sib txuas ntawm cov lej hardness los ntawm cov kev sim sib txawv uas muaj feem cuam tshuam.Hauv txhua qhov ntsuas, tus lej siab hardness sawv cev rau cov hlau tawv.

Thermal Properties ntawm Duplex Stainless Hlau

Cov khoom cua sov ntawm cov ntaub ntawv xa mus rau cov lus teb ntawm cov ntaub ntawv rau kev hloov hauv lawvkubthiab daim ntawv thov ntawmkub.Raws li ib tug khoom absorbszognyob rau hauv daim ntawv ntawm tshav kub, nws kub nce, thiab nws qhov ntev nce.Tab sis cov ntaub ntawv sib txawv teb rau daim ntawv thov ntawm cov cua sov sib txawv.

Thaum tshav kub kub muaj peev xwm,thermal expansion, thiabthermal conductivityfeem ntau tseem ceeb hauv kev siv cov khoom siv.

Melting Point ntawm Duplex Stainless Hlau

Lub melting point ntawm duplex stainless hlau - SAF 2205 steel yog nyob ib ncig ntawm 1450 ° C.

Feem ntau, melting yog ib theem hloov ntawm cov khoom los ntawm cov khoom mus rau cov kua theem.Covmelting pointntawm ib yam khoom yog qhov kub ntawm qhov kev hloov theem no tshwm sim.Lub melting point kuj txhais tau tias cov khoom thiab cov kua muaj nyob rau hauv equilibrium.

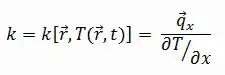

Thermal conductivity ntawm Duplex Stainless hlau

Lub thermal conductivity ntawm duplex stainless hlau - SAF 2205 yog 19 W / (m. K).

Cov yam ntxwv ntawm cov khoom siv hluav taws xob hloov hluav taws xob yog ntsuas los ntawm cov cuab yeej hu uathermal conductivity, k (los yog λ), ntsuas hauv W / mK Nws ntsuas cov khoom muaj peev xwm hloov cov cua sov los ntawm cov khoom siv los ntawmkev coj ua.Nco ntsoov tiasFourier txoj caisiv tau rau txhua qhov teeb meem, tsis hais nws lub xeev (khoom, kua, lossis roj).Yog li ntawd, nws kuj txhais tau rau cov kua thiab gases.

Covthermal conductivityFeem ntau ntawm cov kua thiab cov khoom sib txawv nrog qhov kub thiab txias, thiab rau cov vapors, nws kuj nyob ntawm qhov siab.Feem ntau:

Cov ntaub ntawv feem ntau yog ze li ntawm homogeneous, yog li peb tuaj yeem sau k = k (T).Cov ntsiab lus zoo sib xws yog txuam nrog thermal conductivity nyob rau hauv y- thiab z-directions (ky, kz), tab sis rau ib qho khoom siv isotropic, thermal conductivity yog ywj siab ntawm kev hloov, kx = ky = kz = k.

Post lub sij hawm: Feb-04-2023