Thaum tsim nyob rau hauv ib tug zuj zus tuag, lub workpiece siab, nias tej yam kev mob thiab pib cov ntaub ntawv cuam tshuam lub peev xwm kom tau txais ruaj khov cov txiaj ntsig tsis muaj wrinkles.

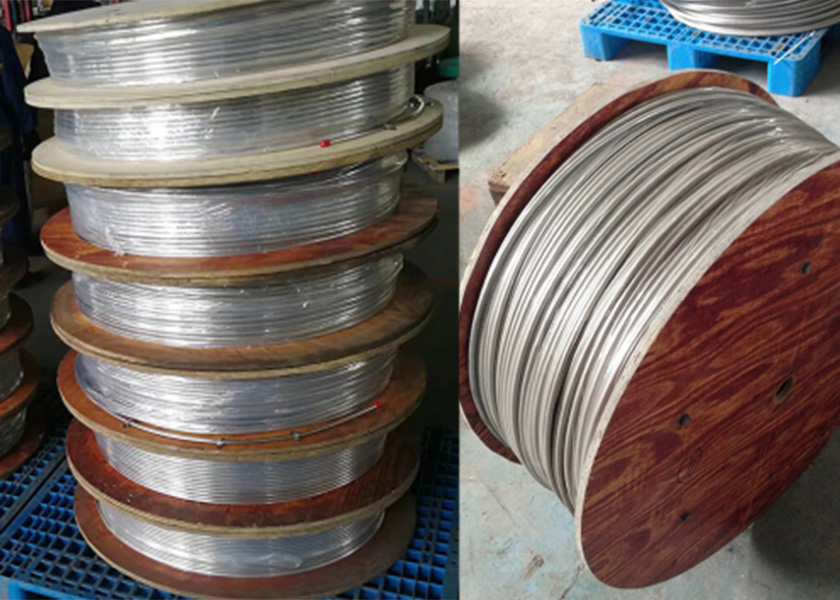

Q: Peb ua lub khob hauv 304 stainless hlau.Ntawm qhov chaw nres tsheb thawj zaug ntawm kev nce qib tuag, peb kos mus txog 0.75 nti tob.Thaum kuv txheeb xyuas qhov tuab ntawm lub pob tw flange perimeter, nws tuaj yeem sib txawv ntawm 0.003 ntiv tes ntawm ib sab mus rau lwm qhov.Txhua qhov ntaus sib txawv thiab tsis tshwm sim hauv tib qhov chaw.Kuv tau hais tias nws muaj qee yam ua nrog rau kev ua cov khoom siv raw, tej zaum sab nrauv ntawm lub ntsiab spool.Yuav ua li cas peb thiaj li tau txais ib khob ntawm qhov zoo li tsis muaj creases?

A: Kuv pom tias koj cov lus nug begs ob nqe lus nug: thawj yog qhov kev hloov pauv uas koj tau txais hauv cov txheej txheem ntawm kev kos duab, thiab qhov thib ob yog cov khoom siv thiab nws cov specification.

Thawj qhov teeb meem yog qhov tsis txaus ntseeg hauv kev tsim cov cuab yeej, yog li cia peb mus dhau qhov hauv paus.Periodic wrinkling thiab fluctuations nyob rau hauv thickness ntawm lub khob flanges tom qab stretching qhia tsis txaus cov cuab yeej sib txuas hauv koj qhov chaw nres tsheb tuag stretching.Yog tsis pom koj tus qauv tuag, kuv yuav tsum xav tias cov punch thiab tuag radii thiab lawv cov clearances raws li tag nrho cov qauv tsim tsis.

Thaum lub sij hawm tus txheej txheem kos duab, lub workpiece yog tuav ntawm lub kos duab tuag thiab ntug yas dhos, thaum lub nqus nqus nqus nqus nqus cov ntaub ntawv mus rau hauv daim duab tuag, rub nws raws lub vojvoog ntawm daim duab los tsim lub plhaub.Kev sib txhuam muaj zog tshwm sim ntawm cov pwm thiab cov khoom ua haujlwm.Thaum lub sij hawm tus txheej txheem no, cov khoom yog raug mus rau transverse compression, uas ua rau wrinkling thiab radial elongation raws li tus ntug tuav nres qhov ntws ntawm cov khoom.Yog tias lub sealing siab dhau lawm, cov khoom yuav tawg nyob rau hauv lub zog rub ntawm lub punch.Yog tias nws qis dhau, wrinkles yuav tshwm.

Kev ua tiav kev kos duab tsis tuaj yeem tshaj qhov kev txwv ntawm lub plhaub taub thiab lub workpiece txoj kab uas hla.Qhov kev txwv no nyob ntawm qhov feem pua elongation ntawm cov khoom.Txoj cai dav dav yog pleev xim 55% txog 60% thawj zaug thiab 20% txhua zaus tom qab ntawd.Ntawm daim duab.1 qhia cov qauv qauv rau kev xam cov preform siab uas yuav tsum tau rau stretching (Kuv ib txwm ntxiv tsawg kawg yog 30% ntxiv quab yuam raws li ib tug kev ruaj ntseg yam. Qhov no yuav txo tau yog tias tsim nyog, tab sis nws yog ib qho nyuaj rau nce tom qab tsim tiav).

Lub siab p yog 2.5 N / mm2 rau hlau, 2.0-2.4 N / mm2 rau tooj liab alloy thiab 1.2-1.5 N / mm2 rau txhuas alloy.

Qhov sib txawv ntawm flange thickness kuj tuaj yeem qhia tau tias koj lub cuab yeej tsim tsis muaj zog txaus.Cov khau pwm yuav tsum yog tuab txaus kom tiv taus qhov nro yam tsis muaj dabtsi yog khoov.Kev txhawb nqa nyob rau hauv cov khau yuav tsum yog cov hlau muaj zog, thiab cov lus qhia pins ntawm cov cuab yeej yuav tsum loj txaus los tiv thaiv kev txav mus los ntawm cov cuab yeej sab saud thiab qis thaum lub sij hawm ncab.

Kuj saib koj cov xov xwm.Yog tias cov ntawv xov xwm hnav thiab xoob, koj yuav tsis ua tiav, txawm tias koj cov cuab yeej muaj zog npaum li cas.Xyuas cov xovxwm pusher kom paub tseeb tias nws yog lawm thiab square thoob plaws qhov ntev ntawm cov xovxwm stroke.Xyuas kom tseeb tias koj daim duab lubricant tau lim thiab nyob rau hauv qhov zoo, thiab tias lub cuab yeej siv tus nqi kom raug thiab txoj haujlwm nozzle raug.Tag nrho cov cuab yeej luam ntawv tau ua tib zoo xyuas kom paub meej tias qhov chaw tiav, kev pab them nqi thiab symmetry.Thiab them nyiaj tshwj xeeb rau kev kos duab radii, lawv yuav tsum muaj cov duab geometry zoo meej thiab kev huv ntawm qhov chaw.

Tsis tas li, thaum cov neeg siv khoom xav tias 304L thiab tus qauv 304 sib hloov tau, 304L yog qhov kev xaiv zoo tshaj plaws rau kev ncab.L stands rau qis carbon, uas muab 304L ib tug 0.2% tawm los zog ntawm 35 KSI, thaum 304 muaj ib tug 0.2% yield zog ntawm 42 KSI.Nrog rau 16% qis zog tawm los, 304L yuav tsum muaj tsawg zog los deform thiab tuav cov pwm thaum lub sij hawm molding txheej txheem.Nws yooj yim dua los siv.

Are you concerned about stamping in the shop or about tools and dies? If so, send your questions to kateb@thefabricator.com and Thomas Vacca, CTO of Micro Co., will answer them.

STAMPING Journal yog ib qho kev lag luam luam tawm tshwj xeeb rau cov kev xav tau ntawm kev lag luam hlau stamping.Txij li thaum xyoo 1989, cov ntawv tshaj tawm tau mob siab rau kev siv thev naus laus zis, kev lag luam tiam sis, kev coj ua zoo tshaj plaws thiab xov xwm los pab cov neeg ua haujlwm stamping ua haujlwm zoo dua.

Kev nkag mus rau digital tag nrho rau FABRICATOR tam sim no muaj, muab kev nkag tau yooj yim rau kev lag luam muaj txiaj ntsig.

Tag nrho cov digital nkag mus rau Tube & Pipe Journal tam sim no muaj, muab kev nkag tau yooj yim rau kev lag luam muaj txiaj ntsig.

Txaus siab rau tag nrho cov digital nkag mus rau STAMPING Journal, cov ntawv xov xwm kev lag luam hlau stamping nrog cov thev naus laus zis tshiab, kev coj ua zoo tshaj plaws thiab xov xwm kev lag luam.

Kev nkag mus rau Tus Fabricator en Español cov ntawv luam tawm tam sim no muaj, muab kev nkag tau yooj yim rau cov peev txheej lag luam muaj txiaj ntsig.

Nyob rau hauv thawj ib feem ntawm peb ob-series series, hlau artist thiab welder Ray Ripple koom nrog tus tswv tsev Dan Davis…

Post lub sij hawm: Jan-03-2023