Alloy 625 Stainless Hlau Coil Tubing Nqe

Tshuaj muaj pes tsawg leeg,%

Alloy 625 cov khoom siv tsis yog hlau nplaum, austenitic, thiab nthuav tawm lub zog tensile siab, fabricability, thiab brazeability.Vim nws cov ntsiab lus siab nickel, cov hlau no yuav luag tsis muaj zog tiv thaiv chloride ion kev ntxhov siab-corrosion tawg thiab pitting, uas feem ntau pom muaj nyob rau hauv cov hlau hauv seawater daim ntaub ntawv xws li tshav kub exchangers, fasteners, thiab cable sheathing.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 Nws | Tseem tshuav | 8.0-10.0 Nws | 1.0 max | 3.15-4.15 dr hab | .40 max | .40 max | .10 max |

| Fe | Mn | Si | P | S |

| 5.0 max | .50 max | .50 max | 015 max | 015 max |

Inconel 625 siv hauv daim ntawv thov twg?

- Inconel 625 feem ntau yog siv hauv Aerospace kev lag luam

- Aircraft ducting systems

- Dav hlau tshuab tso pa system

- Cav thrust-reverser systems

- Cov khoom siv dej hiav txwv tshwj xeeb

- Cov cuab yeej siv tshuaj

ASTM Cov Lus Qhia

| cev Smls | Cov yeeb nkab Welded | Tube Smls | Tube Welded | Ntawv / phaj | Bar | Forging | Haum | Hlau |

| b444 ua | b705 ua | b444 ua | b704 ua | b443 ua | b446 ua | - | - | - |

Mechanical Properties

| Temp ° F | Tensile (psi) | .2% Tawm (psi) | Elongation hauv 2 "(%) |

| 70 | 144,000 Nws | 84,000 ib | 44 |

| 400 | 134,000 Nws | 66,000 ib | 45 |

| 600 | 132,000 Nws | 63,000 ib | 42.5 ib |

| 800 | 131.500 Nws | 61,000 ib | 45 |

| 1000 | 130,000 ib | 60,500 ib | 48 |

| 1200 | 119,000 Nws | 60,000 | 34 |

| 1400 | 78,000 ib | 58,500 ib | 59 |

| 1600 | 40,000 | 39,000 ib | 117 |

Inconel 625 Melting Point

| Melting Point | 1290-1350 ° C | 2350 - 2460 ° F |

Inconel 625 sib npaug

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Ib 625 | 2.4856 ib | n06625 ua | SIB 625 | NA 21 | ХН75MБТЮ | NC22DNB4MNiCr22Mo9Nb | NiCr23Fe |

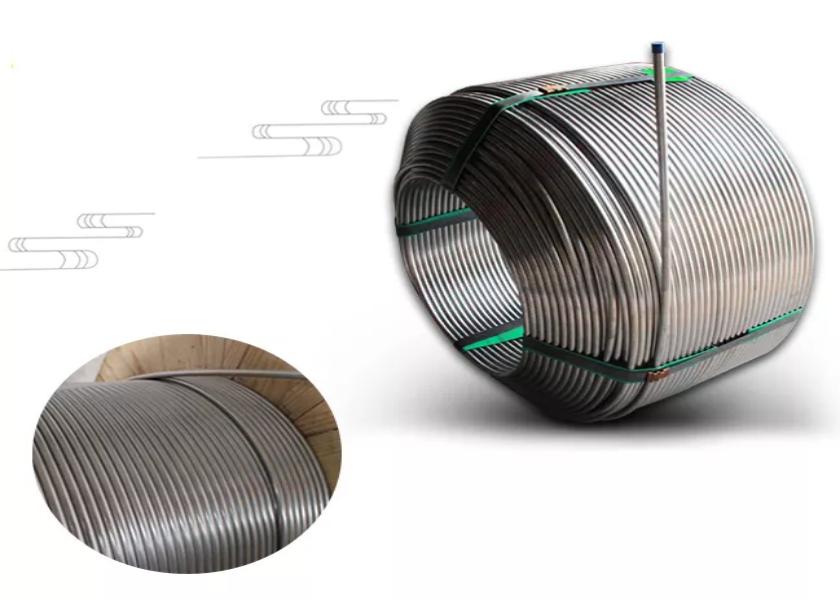

Alloy 625 Tubing

Alloy 625 yog ib qho austenitic npib tsib xee-chromium-molybdenum superalloy paub txog kev tiv thaiv rau crevice corrosion thiab oxidation ntawm qhov kub thiab txias.Cov kub no tuaj yeem nyob ntawm qhov kub thiab txias ntawm 1,800 ° F.Tus cwj pwm thiab tshuaj lom neeg muaj pes tsawg leeg ntawm qib no ua rau nws zoo haum rau kev siv nuclear thiab aerospace.Tsis tas li ntawd, nrog rau qhov sib ntxiv ntawm niobium, alloy 625 tubing pom nws tus kheej nrog lub zog muaj zog tsis muaj kev kho cua sov.Cov cuab yeej no ua rau qib ib qho kev xaiv zoo tshaj plaws rau kev tsim khoom.

Khoom Specifications

ASTM B444 / ASME SB444 / NACE MR0175

Qhov Loj

| Sab nraud Diameter (OD) | Phab ntsa Thickness |

| 375 "-.750" | .035 "-.095" |

Kev xav tau tshuaj

Cov alloy 625 (UNS N06625)

Cov ntsiab lus %

| C Cov pa roj carbon | Mn Manganese | Si Silicon | P Phosphorous | Cr Chromium | Nb+Ta Niobium-tantalum | Co Cobalt | Mo Molybdenum | Fe Hlau | Al Aluminium | Ti Titanium | Ni Nickel |

| 0.10 max | 0.50 max | 0.50 max | 0.015 max | 20.0-23.0 Nws | 3.15–4.15 dr hab | 1.0 max | 8.0–10.0 Nws | 5.0 max | 0.40 max | 0.40 max | 5 8,0mn |

Dimensional Tolerances

| OD | OD Tolerance | Phab ntsa Tolerance |

| 375 "- 0.500" excl | +.004 "/-.000" | ± 10% |

| 0.500 "- 1.250" excl | +.005 "/-.000" | ± 10% |

Mechanical Properties

| Yield zog: | 60 kwm |

| Tensile zog: | 120 hli min |

| Elongation (min 2 "): | 30% |

Factoy Duab

Kev tshuaj xyuas

Shipping & Packing

Test Report