Alloy 600 Stainless Hlau Coil Tubing Nqe

Tshuaj muaj pes tsawg leeg,%

Cov ntawv thov kev txhim kho corrosion xws li titanium dioxide ntau lawm (chloride txoj kev), perchlorethylene syntheses, vinyl chloride monomer (VCM), thiab magnesium chloride.Alloy 600 yog siv rau hauv kev tsim tshuaj thiab khoom noj khoom haus, kev kho cua sov, phenol condensers, xab npum tsim, zaub thiab fatty acid hlab ntsha thiab ntau ntxiv.

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 7 2,0mn | 14.0-17.0 Nws | 6.0-10.0 Nws | .15 max | max 1.00 Nws | 015 max | .50 max | .50 max |

Inconel 600 siv hauv daim ntawv thov twg?

- Kev lag luam tshuaj

- Aerospace

- Kev kho cua sov kev lag luam

- Pulp thiab ntawv kev lag luam

- Kev ua zaub mov

- Nuclear Engineering

- Gas turbine Cheebtsam

ASTM Cov Lus Qhia

| cev Smls | Cov yeeb nkab Welded | Tube Smls | Tube Welded | Ntawv / phaj | Bar | Forging | Haum | Hlau |

| B167 | b517 ua | B163 | B516 | B168 | B166 | b564 ua | B366 |

Mechanical Properties

Yam chav tsev kub Tensile Properties ntawm Annealed Material

| Daim ntawv khoom | Qhov xwm txheej | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) | Hardness (HRB) |

| Qws & Bar | Txias-Drawn | 80-100 | 25-50 | 35-55 : kuv | 65-85 : kuv |

| Qws & Bar | Kub-Tiav lawm | 80-100 | 30-50 | 35-55 : kuv | 65-85 : kuv |

| Tube & Yeeb | Kub-Tiav lawm | 75-100 : kuv | 25-50 | 35 * 55 | - |

| Tube & Yeeb | Txias-Drawn | 80-100 | 25-50 | 35-55 : kuv | 88 Max |

| Phaj | Kub Rolled | 80-105 : kuv | 30-50 | 35-55 : kuv | 65-85 : kuv |

| Daim ntawv | Txias-Drawn | 80-100 | 30-45 : kuv | 35-55 : kuv | 88 Max |

Inconel 600 Melting Point

| Element | Qhov ntom | Melting Point | Tensile zog | Yield zog (0.2% Offset) | Elongation |

| Alloy 600 | 8,47g 3 | 1413 ° C (2580 ° F) | Psi - 95,000, MPa - 655 | Psi - 45,000, MPa - 310 | 40% |

Inconel 600 sib npaug

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Alloy 600 | 2.4816 ib | N06600 | NCV 600 | NA 13 | Peb 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Alloy 600 Tubing

Alloy 600 yog ib tus neeg sib tw zoo tshaj plaws rau kev siv ntau yam hauv qhov kub thiab txias heev.Kev sib xyaw ntawm npib tsib xee thiab chromium yields cov khoom tiv thaiv oxidation hauv kev ua haujlwm kub.Cov kub no tuaj yeem nyob ntawm qhov kub thiab txias ntawm 2,000 ° F.Lub siab nickel cov ntsiab lus ntawm alloy 400 kuj muaj ze li ntawm kev tiv thaiv kev ntxhov siab corrosion, uas feem ntau pom nyob rau hauv ib puag ncig chloride.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias qhov chromium feem ntawm cov hlau alloy cov tshuaj profile ua rau nws ua tau rau qib kom tiv taus qhov kub thiab txias.Lub finer grain qauv ntawm txias tiav tube, ntxiv rau, coj zoo corrosion kuj, uas muaj xws li kev qaug zog ntau dua thiab cuam tshuam qhov tseem ceeb ntawm lub zog.

Khoom Specifications

ASTM B163, B167, ASME SB163, NACE MR0175, MR0103

Qhov Loj

| Sab nraud Diameter (OD) | Phab ntsa Thickness |

| 250 "-.750" | .035 "-.083" |

Kev xav tau tshuaj

Hlau alloy 600 (UNS N06600)

Cov ntsiab lus %

| Ni Nickel | Cu Tooj | Fe Hlau | Mn Manganese | C Cov pa roj carbon | Si Silicon | S Sulfur | Cr Chromium |

| 7 2,0mn | 0.50 max | 6.00–10.00 Nws | max 1.00 Nws | 0.15 max | 0.50 max | 0.015 max | 14.0-17.0 Nws |

Dimensional Tolerances

| OD | OD Tolerance | Phab ntsa Tolerance |

| ≤ .500 "excl | +.005" | ± 12.5% |

| .500 "-.750" excl | +.005" | ± 12.5% |

Mechanical Properties

| Yield zog: | 35 kwm |

| Tensile zog: | 80 kwm |

| Elongation (min 2 "): | 30% |

Fabrication

Alloy 600 tuaj yeem yooj yim welded los ntawm txheej txheem txheej txheem.Kev tswj hwm ntawm cov hlau no zoo heev, nyob nruab nrab ntawm kev siv hluav taws xob ntawm T303 thiab T304.

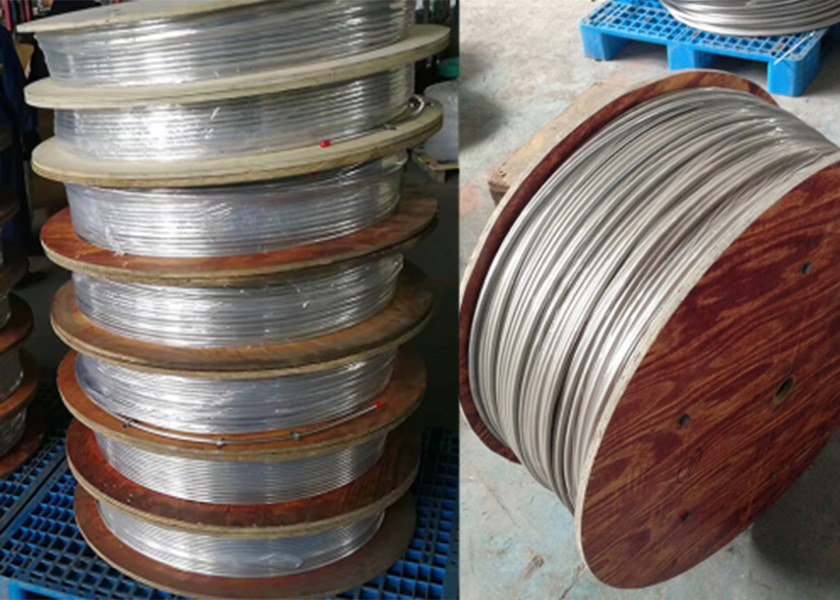

Factoy Duab

Kev tshuaj xyuas

Shipping & Packing

Test Report