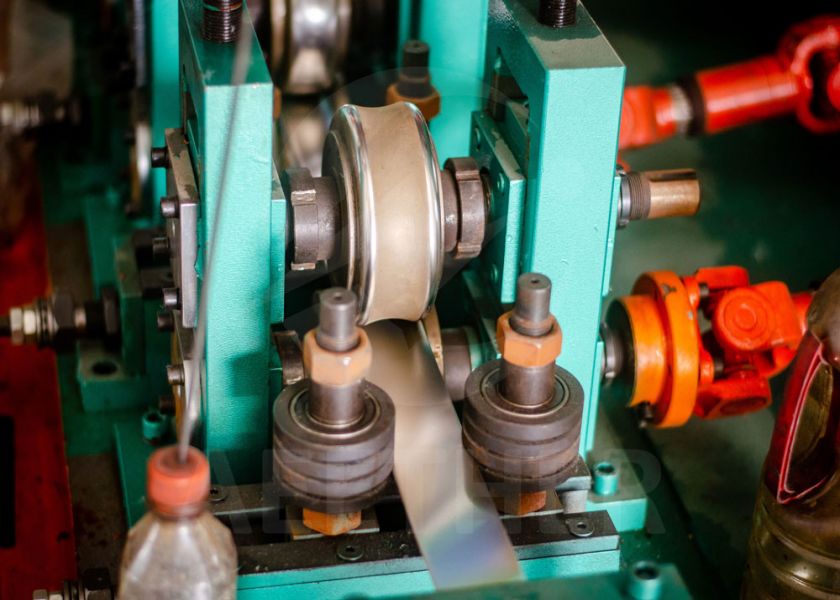

321 stainless hlau 5 * 1.2mm capillary tubing

Alloy 321 (UNS S32100) yog a

titanium stabilized austenitic

stainless hlau nrog zoo general

corrosion kuj.Nws muaj zoo heev

tsis kam mus rau intergranular corrosion

tom qab raug rau qhov kub thiab txias

chromium carbide nag lossis daus

321 stainless hlau 5 * 1.2mm capillary tubing

Qhov kub ntawm 800-1500 ° F (427-816 ° C).

Cov hlau tiv thaiv oxidation rau 1500 ° F

(816 ° C) thiab muaj qhov nkag siab dua thiab

kev nyuaj siab rupture zog dua alloys

304 thiab 304 L.Nws kuj muaj

zoo tsawg kub toughness.

Alloy 321H (UNS S32109) yog cov

siab dua carbon (0.04–0.10) version of

lub alloy.Nws yog tsim los rau

enhanced creep kuj thiab rau

siab zog ntawm qhov kub thiab txias

Tshaj 1000 ° F (537 ° C).Hauv feem ntau

Piv txwv li, cov ntsiab lus ntawm cov pa roj carbon

phaj enables dual ntawv pov thawj.

Alloy 321 tsis tuaj yeem hardened los ntawm

Kev kho cua sov, tsuas yog los ntawm kev ua haujlwm txias.

Nws tuaj yeem yooj yim welded thiab

txheej txheem los ntawm lub khw

cov kev ua si.

Daim ntawv thov

• Aerospace

- piston cav

manifolds

• Kev ua tshuaj lom neeg

• Extension Joints

• Kev ua zaub mov—cov khoom siv

thiab khaws cia

• Petroleum Refining—polythionic

acid kev pab

• Kev kho khib nyiab—kub kub

oxidizers

Cov qauv

321 stainless hlau 5 * 1.2mm capillary tubing

ASTM ……………..A 240

ASME …………….. SA 240

UAS ……………….5 510

Tshuaj ntsuam xyuas

Qhov hnyav % (tag nrho cov txiaj ntsig yog qhov siab tshaj plaws tshwj tsis yog muaj ntau yam qhia)

Daim ntawv qhia tshwj xeeb: Alloy 321/321H

(UNS S32100, S32109) W. Nr.1.4541 ib

Titanium Stabilized Austenitic Stainless Hlau nrog Kev Ua Haujlwm Zoo

mus rau Intergranular Corrosion Tom qab raug rau kub nyob rau hauv lub

Chromium Carbide Precipitation Range ntawm 800-1500 ° F (427-816 ° C)

321 stainless hlau 5 * 1.2mm capillary tubing

Alloy 321 06/2014

rev 02/2023 PDF link

Lub cev muaj zog

Qhov ntom

0.286 lbs / hauv 3

7.920 g / cm3

Modulus ntawm Elasticity

28.0 x 106 psi

193 gp ua

Melting Range

2550-2635 ° F

1398-1446 ° C

Tshwj xeeb kub

0.12 BTU/lb-°F (32–212°F)

500 J / kg - ° K (0-100 ° C)

Thermal conductivity 212 ° F (100 ° C)

9.3 BTU / teev / ft2 / ft / ° F

16.0 W / m-°K

Hluav taws xob Resistivity

72 Microhm-cm ntawm 20 ° C

Mechanical Properties

Tus nqi zoo ntawm 68 ° F (20 ° C)

Qhov kub thiab txias

° F

°C

hauv / hauv ° F

cm / cm ° C

68–212 : kuv

20–100

9.2 x 10-6

16.0 x 10-6

68–1112 : kuv

20-600 Nws

10.5 x 10-6

18.9 x 10-6

68–1832 : kuv

20-1000 Nws

11.4x 10-6

20.5 x 10-6

Yield zog

Qhov kawg Tensile

Elongation

Hardness

0.2% Tawm

Lub zog

ua 2in.

psi (min.)

(MPa)

psi (min.)

(MPa)

% (min.)

(max.)

30,000

205

75,000 ib

515

40

217 Ib

Sau koj cov lus ntawm no thiab xa tuaj rau peb