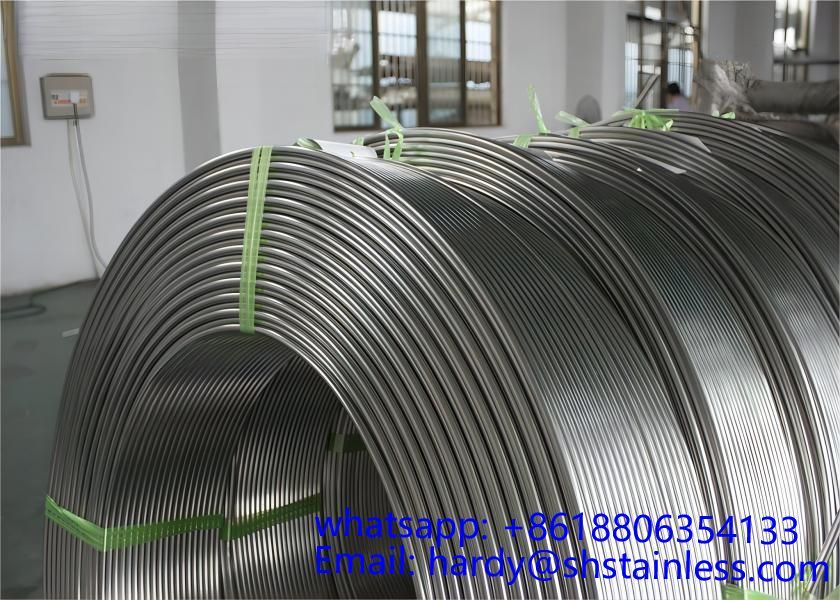

2507 stainless hlau 10 * 1mm coiled capillary tubing

KHOOM PLIG

2507 stainless hlau 10 * 1mm coiled capillary tubing

Tag nrho peb cov ntaub ntawv super-duplex yog tsim los ntawm Norsok M-650 Ed.4 thiab / lossis ISO 17782 cov tuam txhab tsim nyog.

Super Duplex UNS S32750 yog qib super duplex tshaj plaws hauv khw.UNS S32750 yog ib qho duplex tshwj xeeb tshaj yog tsim los rau kev pabcuam hauv cov cheeb tsam uas muaj cov tshuaj chloride.Nws muaj kev tiv thaiv zoo heev rau thaj tsam corrosion thiab kev ntxhov siab corrosion tawg ua ke nrog cov neeg kho tshuab siab zog.Nws yog dav siv nyob rau hauv roj & roj, hydropower, siab hlab ntsha, pulp & ntawv, structural Cheebtsam thiab tshuaj tankers.

Daim ntawv thov

2507 stainless hlau 10 * 1mm coiled capillary tubing

Cov ntawv thov tseem ceeb yog kom paub meej nrog cov kev cai tshwj xeeb rau kev ua haujlwm siab corrosion.

UNS S32750 yog tus cwj pwm los ntawm:

- Siab tsis kam rau kev ntxhov siab corrosion tawg hauv halide uas muaj ib puag ncig.

- Siab tiv taus pitting thiab crevice corrosion.

- Siab tsis kam mus rau general corrosion.

- High mechanical zog.

- Siab tiv taus corrosion corrosion thiab qaug zog corrosion.

Thaum tshav kub kub kho 2507 stainless hlau 10 * 1mm coiled capillary tubing

Kev daws annealing nyob rau hauv thaj tsam ntawm 1100 ° C tom qab dej quenching.

Weldability

Zoo heev.

Chemical Composition (Tshwj xeeb rau Bars)

| Qhov hnyav% | C | Mn | P | S | Si | Cr | Ni | Mo | Cu | N | PRE |

| Min. | 24,0 ib | 6,00 Nws | 3,00 ib | 0,24 ib | 41 | ||||||

| Max. | 0,030 ua | 1,20 | 0,025 ib | 0,010 ib | 0,80 ua | 26,0 ib | 8,00 Nws | 4,50 ib | 0,50 ib | 0,32 ib |

PREN = % Cr + 3.3 % Mo + 16 % N ≥ 41

Cov qauv siv

General:

- Norsok M-650 Ed.4 tsim nyog manufacturers

- PED 2014/68/EU Annex I ntu 4.3

- AD 2000 W0 (W2/W10)

- NACE MR0175 / ISO 15156-3 thiab NACE MR0103 / ISO 17945

- 2507 stainless hlau 10 * 1mm coiled capillary tubing

Phaj, ntawv thiab coil:

- ASTM A240, EN 10028-7, EN 10088-2, EN 10088-4, Norsok M-630 MDS D55

Bar thiab forging:

- ASTM A276, ASTM A479, ASTM A182, EN 10088-3, Norsok M-630 MDS D54 / D57

Lwm cov khoom siv:

- Raws li ASTM thiab / lossis EN cov qauv siv tau thiab Norsok M-630 MDS

Mechanical Properties (Tswj)

| Yield zog Rp0.2, MPa | Tensile zog Rm, MPa | Elongation [%] | Hardness [HB] | Kev cuam tshuam, Charpy-V, -46ºC [J] | |

| BAR | ≥ 550 | ≥750 | ≥ 25 | ≤ 300 | ≥ 65 |

| Plate CR (COIL) | ≥ 550 | 750-1000 Nws | ≥ 25 | ≤ 310 | ≥ 45 |

| PHAJ HR (COIL) | ≥ 550 | 750-1000 Nws | ≥ 25 | ≤ 310 | ≥ 45 |

| PLATE (QUARTO) | ≥ 550 | 750-930 : kuv | ≥ 25 | ≤ 310 | ≥ 45 |