1070 aluminium coiled raj

Kev kho cua sov txheej txheem rau 1070

roj quenching thiab tempering.Lub zog ntawm hom hlau hlau no tsis zoo li cov hlau lead da dej kho steel hlau, tab sis cov khoom tsis sib xws thiab tus nqi qis.Tom qab txias yob txoj kev, qhov kev ntxhov siab raug tshem tawm.Rub mus rau qhov loj me, thiab tom qab ntawd anneal.Cov cuab yeej kho tshuab ntawm cov coil softened tau tsuas yog tom qab quenching thiab tempering ntawm nruab nrab kub.

Cov yam ntxwv thiab kev siv rau 1070

Nws muaj cov yam ntxwv ntawm high plasticity, corrosion resistance, zoo conductivity thiab thermal conductivity, tab sis tsis tshua muaj zog, tsis muaj zog los ntawm kev kho cua sov, machinability tsis zoo, thiab tuaj yeem txais kev sib cuag vuam thiab roj vuam.Ua kom siv ntau dua ntawm nws qhov zoo los tsim qee qhov chaw nrog kev ua haujlwm tshwj xeeb, xws li txhuas ntawv ci ua gasket thiab capacitor, electron tube rho tawm net, hlau, cable tiv thaiv npog, net, hlau core thiab aircraft qhov cua qhov system qhov chaw thiab cov khoom zoo nkauj.

Specifications

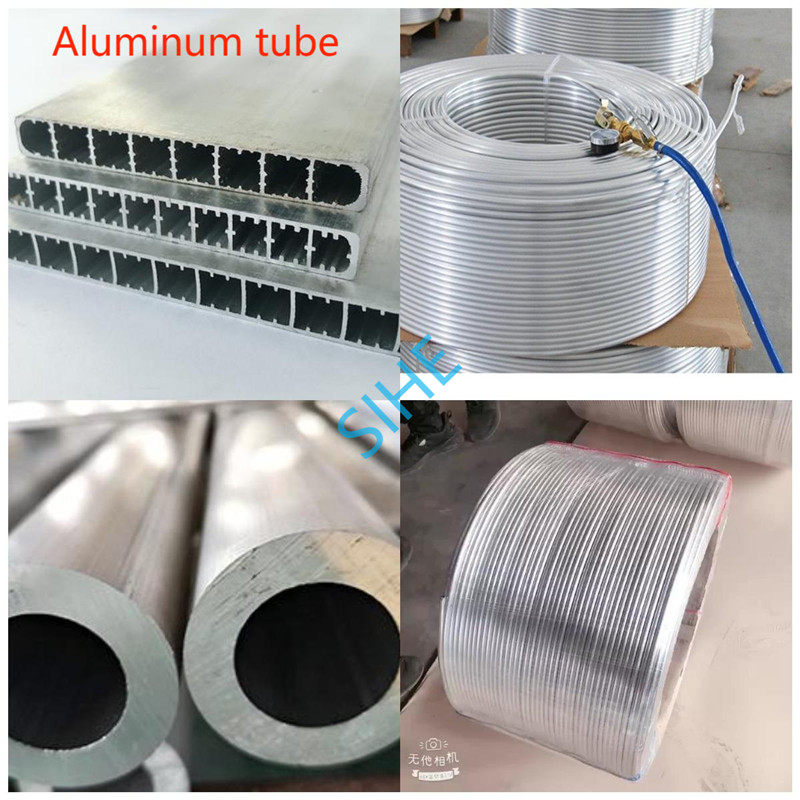

Hom Specification ntawm Aluminium Tube

| Alloy Tsis muaj. | Kub | Ncaj Tube | LWC | ||

| OD (mm) | WT (mm) | OD (mm) | WT | ||

| 1060 (L2) | R (H112) | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| M (O) | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H 14 | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| 3 A21 3003 3103 (LF21) | M (O) | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| H12 | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H14 | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H18 | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| ib 6063 (LD31) | M (O) | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 |

| T4 | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

| T6 | 6-30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

Specification ntawm Inner Groove Aluminium Tube (Qhov loj tuaj yeem kho)

| Specification (hli) | Phab ntsa thickness (mm) | Grooved Qhov siab (mm) | Lub kaum ntse ntse (°) |

| 7 | 0.4-0.5 hli | 0.05-0.18 dr hab | 18 |

| 7.94 ib | 0.4-0.5 hli | 0.05-0.18 dr hab | 18 |

| 9.52 ib | 0.45-0.55 Nws | 0.05-0.18 dr hab | 18 |

Mechanical Properties ntawm Inner Aluminium Grooved Tube

| Khoom siv | Tensile | Elongation tus nqi | Expanding Rate |

| 3003 | 130 MPA | 35 | 40 |

Specification ntawm Pob Coil

| OD | 6.35 Nws | 7.94 ib | 9.52 ib | 12.7 ib | 15.88 Nws | 19.05 Nws |

| Phab ntsa Thickness | 0.7-1.0 Nws | 0.8-1,2 | 0.8-1.2 hli | 1-1.5 | 1-1.5 | 1-1.5 |

quanlity lav

1) nto zoo li: tiaj tus huv si nto tsis muaj tag nrho, khawb, roj qias neeg los yog oxidation.

2) txiav ntug: zoo zoo txiav ntug tsis muaj burrs.

3) Lub hom phiaj zoo: frist khoom tshuaj xyuas tus nqi tsim nyog yog 98%.Cov neeg siv khoom txaus siab los ntawm 95%.Khoom siv: A1050, A1060, A1070, A3003, thiab lwm yam

| A1050 Aluminium Chemical Muaj pes tsawg leeg | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Lwm tus |

| 99.5-100 | 0-0.25 Nws | 0-0.05 Nws | 0-0.05 Nws | 0-0.05 Nws | 0-0.05 Nws | 0-0.03 Nws | 0-0.05 Nws | 0-0.40 Nws | 0-0.03 Nws |

| A1060 Aluminium Chemical Muaj pes tsawg leeg | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Lwm tus |

| 99.6-100 | 0-0.25 Nws | 0-0.05 Nws | 0-0.03 Nws | 0-0.05 Nws | 0-0.03 Nws | 0-0.03 Nws | / | 0-0.35 Nws | |

| A1070 Aluminium Chemical Muaj pes tsawg leeg | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Lwm tus |

| 99.7-100 | 0 ~ 0.2 hli | 0-0.04 Nws | 0-0.03 Nws | 0-0.04 Nws | 0-0.03 Nws | 0-0.03 Nws | 0-0.05 Nws | 0-0.25 Nws | |

| A3003 Aluminium Chemical Muaj pes tsawg leeg | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Lwm Tiam Single | |

| lwm tus | 0 ~ 0.6 hli | 0.05-0.20 Nws | 0 ~ 0.1 hli | 1.0 ~ 1.5 hli | 0-0.70 Nws | 0-0.05 Nws | |

| Alloy | Kub | Specification | |||

| Thickness (hli) | Txoj kab uas hla (mm) | Tensile zog | Hardness | ||

| 7075 7005 (tub) | T5, T6, T9 | > 0.5 | 5.0-80 Nws | > 310 Mpa | > 140 |

| 6061 6063 (cov duab) | t5,t6 | > 1.6 | 10-180 Nws | > 572 Mpa | HB90-110 |

| Ntev: <6 Meter | |||||

| TEMPER | Thickness (mm) | TENSILE HEEV | ELONGATION% | Txuj |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 : kuv | ≥ 4 | |

| T9 | 0.5-6 | 85-120 : kuv | ≥ 2 |

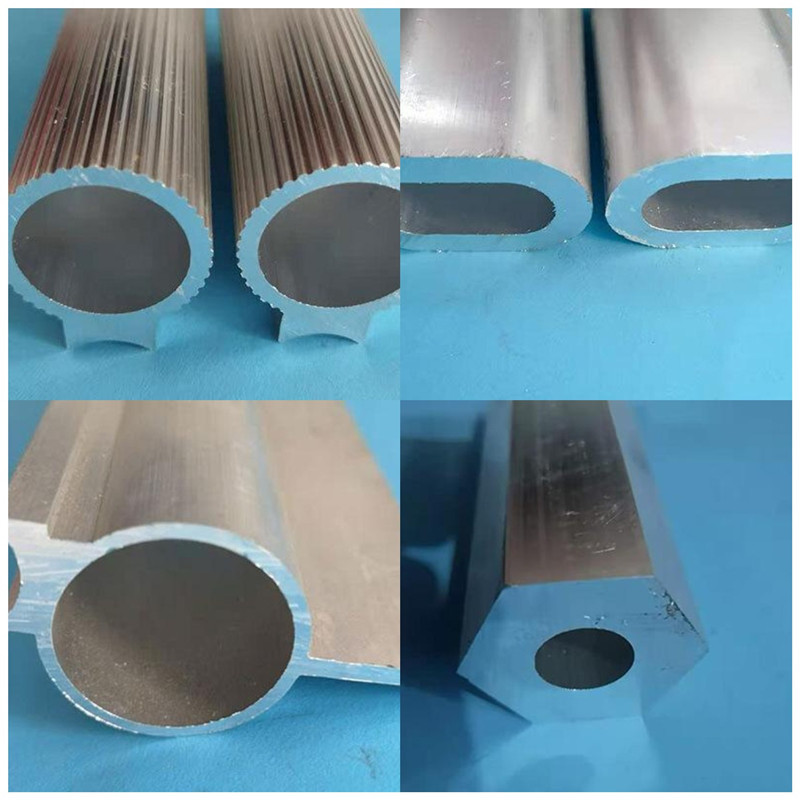

Cov khoom siv aluminium